Smart Welding –

Smart Welding is the leading-edge technology in producing ultrasonically welded connections via ultrasonic metal welding (USMW/UMW). It is used in a variety of microelectronics applications, mostly for establishing electrical connections.

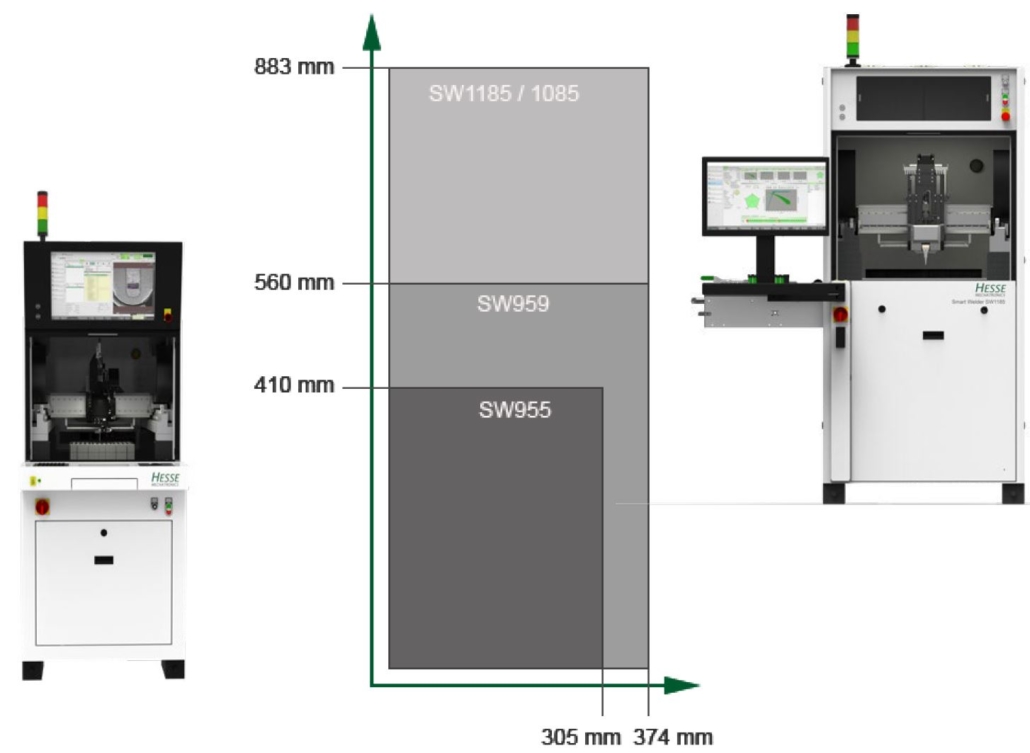

Smart Welding works at high speeds with precise process control and highest accuracies in ultrasonic metal welding. The ease of handling tolerances and the flexible design of the equipment make it beneficial for battery module and pack production. Smart Welders are available with different power levels and in different working areas. Ideal for battery packs, Smart Welders can be used to weld connectors on cell and pack level such as (flexible) bus bars and tabs that connect battery management systems (BMS) and voltage sense contacts. A continuous quality and process monitoring enables all requirements of traceability according to semiconductor and automotive industry standards.

Applications:

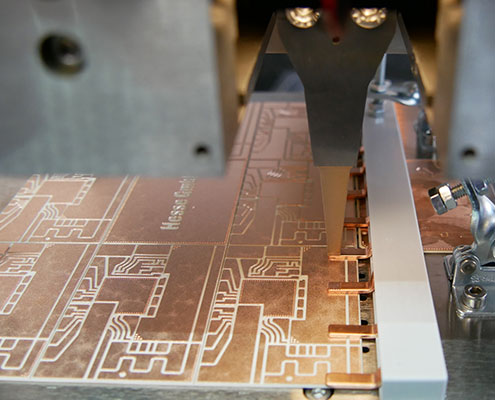

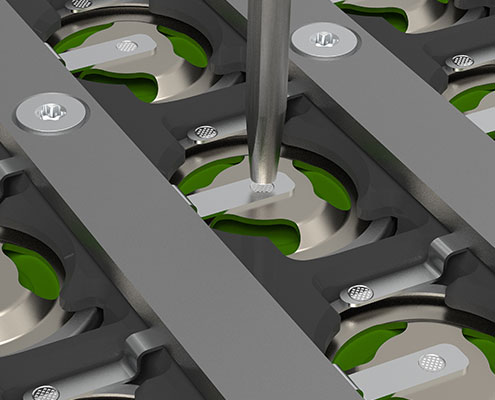

While some applications require ultrasonic power in the upper kW-range, in the packaging of semiconductor modules only relatively low ultrasonic power input is needed to weld its terminals. Such powers from 100W up to 1.5kW cover also smaller stranded wires or thin sheets of copper like used in battery cell contacting systems. To cover these applications smart ultrasonic welding was developed.

These applications below are found in many products of power electronics and battery powered motion, such as air mobility vehicles, forklifts, e-bikes, e-trucks and electric cars. The following section shows some example applications: